Engines are very heavy objects being made from cast iron and steel. A typical diesel engine will weigh 140 kilos and a marine engine with a gearbox and heat exchanger attached could be up to 190kilos. So, how does one lift an engine from the boat’s engine bay so that it can be removed from the boat.

It has been done by Lots and Lots of people

Of course it has, so we can search on YouTube and find plenty of boaters and engineers who have shared their experiences. That’s what I did, but no 2 situations are the same and mine is a steel cruiser without sails and I don’t have a boom that can be used as a crane! Further, I have a narrow entrance to the wheelhouse with steps.

Building a gantry

So, in my situation, I am unable to get above the engine bay from outside the boat, so the solution was to construct a gantry inside. I am fortunate to have some old timber from dismantled childrens’ bunk beds (yes, they have grwon up now). My solution was to build a pair of triangular structures to support a 100mm x 50mm length of timber (rescued from a skip). I also supplemented this with a cross brace perpendicular and over to the upper helm access opening.

This constructed gantry was enough to get the engine up onto the floor of the saloon.

Once the engine was lifted up then the floor had to put back under the swinging engine and then let back down onto a trolley.

Why a trolley?

Perspectief has an offset entrance so the engine needed be shifted from the centre to the port side ready to lifted out by crane.

Take a look here. I hope you get the idea.

I was not able to film the craning out of the engine.

Cleaning up the engine bay

The new engine is on order so now I have time to prepare the engine bay.

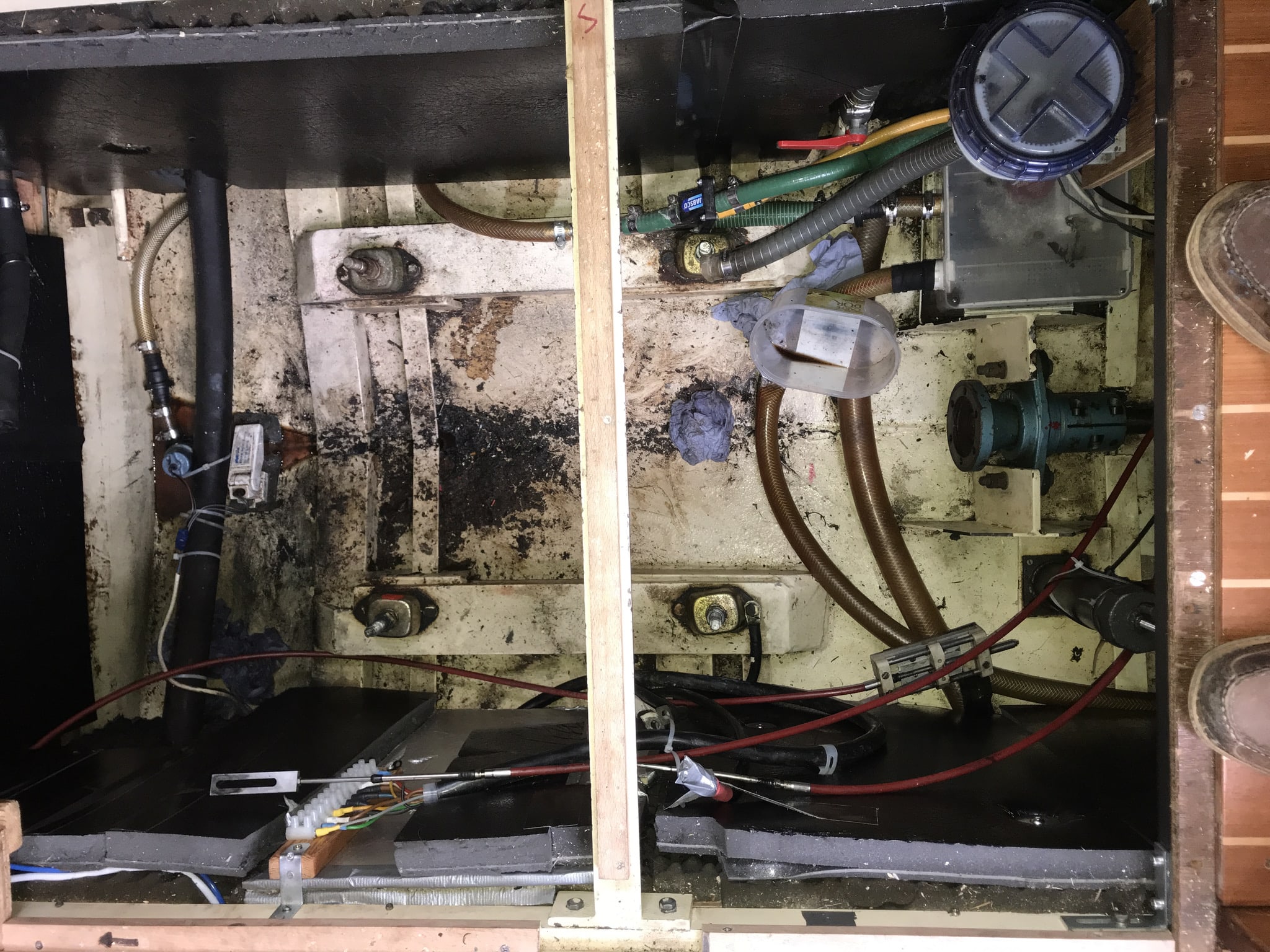

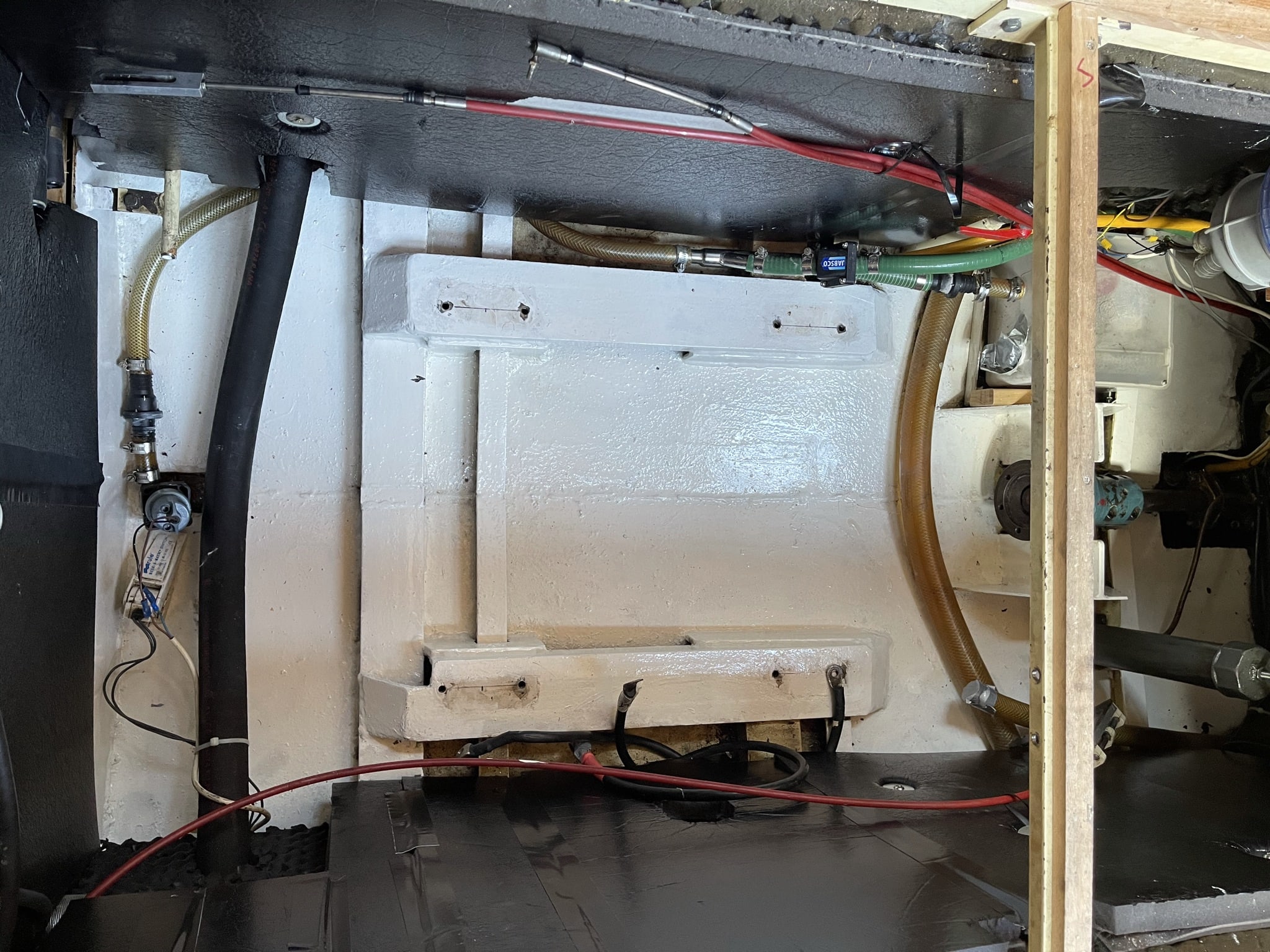

Here are a couple of before and after pictures. I used some bilge cleaner and bilge paint. No poit in putting a new ingine into a dirty engine bay!

Now let’s see what it looks like now.

Next stage is taking delivery of the new engine and craning that in.